Low Price Aluminum Alloy Auto Parts

PRODUCT SPECIFICATION

| DIAMETER | Customized |

| THICKNESS | OEM size |

| SURFACE TREATMENT | Powder coating / Electrophoretic paint |

| COLOUR | OEM color |

| MATERIAL | Aluminum |

| TECHNOLOGY | Aluminum Die Casting |

| APPLICATION | Cars / Trucks / Auto parts |

ADVANTAGES OF OUR CASTING PROCESS

1. Close Tolerance

Our castings are made in metal molds so dimensional variation from piece to piece is negligible and close tolerance is consistently held. Our ability to achieve the highest accuracy and precision has allowed us to successfully cast many parts that have been used without machining, resulting in remarkable savings for our customers.

2. High Quality

Process control and upfront engineering are the keys to guaranteeing high-quality castings. This is probably why Gupta Permold exceeds the industry standards for internal scrap and failure rates. In summary, Gupta Permold strives for Zero-Defects by continuously monitoring all processing and investing painstaking effort into tooling development and designs.

3. Complex Shapes

complex

Our molds are machined out of blocks of high-grade steel. As evidenced by the casting above, complex shapes with thin walls can be cast using ingenious coring techniques so no machining is needed. Undercuts are routinely cast with the use of sand cores, and sometimes, even without. Fully machined cavities, intricate coring techniques, and state-of-the-art molding make complex aluminum parts a routine task for Gupta Permold.

PACKAGING & PAYMENT TERMS & SHIPPING

1.Packaging Detail:

a.clear bags inner packing, cartons outer packing, then pallet.

b.as per customer's demand for hardware stamping parts.

2.Payment:

T/T,30% deposits advance; 70% balance before delivery.

3.Shipping :

1.FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2.By Air or by Sea for batch goods, for FCL;Airport/ Port receiving;

3.Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

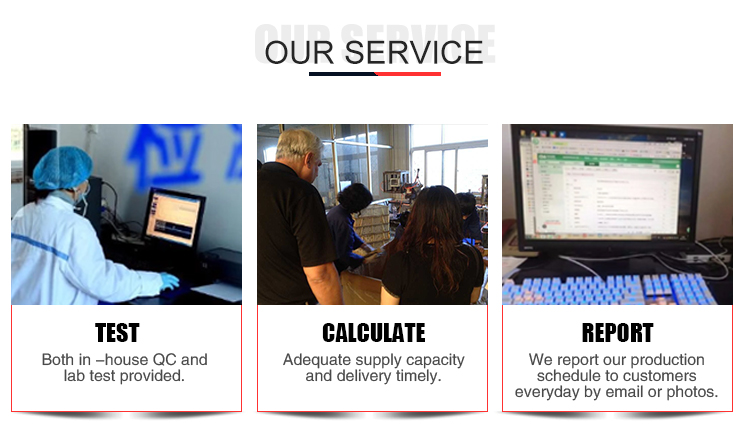

WHY CHOOSE US

POWDER COATING

Out-gassing

When powder coating is applied to our products, we are able to minimize the out gassing which generally occurs and is known to lead to unsightly pinholes. This is mainly due to Gupta’s advanced electrical melting techniques, metal cleanliness practice, and superior aluminum grain structure.

FACTORY SHOW