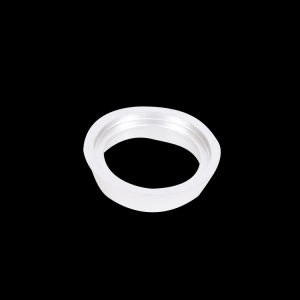

Zinc Alloy Die Casting Parts Free Sample

PRODUCT SPECIFICATION

| HARDNESS | 58-62HRC |

| APPLICATION | Machinery |

| SURFACE TREATMENT | Polishing |

| COLOUR | Aluminum natural color |

| MATERIAL | Aluminum |

| TECHNOLOGY | Cast Aluminum |

| FEATURE | Stable Performance : low Voice |

ADVANTAGES OF OUR ALUMINUM BEARING BLOCK

Good combination of casting, mechanical, and thermal properties.

Excellent fluidity, pressure tightness, and resistance to hot cracking.

PACKAGING & PAYMENT TERMS & SHIPPING

1.Packaging Detail:

a.clear bags inner packing, cartons outer packing, then pallet.

b.as per customer's demand for hardware stamping parts.

2.Payment:

T/T,30% deposits advance; 70% balance before delivery.

3.Shipping :

1.FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2.By Air or by Sea for batch goods, for FCL;Airport/ Port receiving;

3.Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

WHY CHOOSE US

FAQ

I know you have many questions about our R&H. Never mind, I believe you will find the satisfied answer here. If there is no such questions you want to ask, please don’t hesitate to contact us by email or online.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A:Mold lead time:Within 30days upon we receive the 50% of mold charges. Batch production lead time: With 15days upon we receive the 30% deposit.

FACTORY SHOW